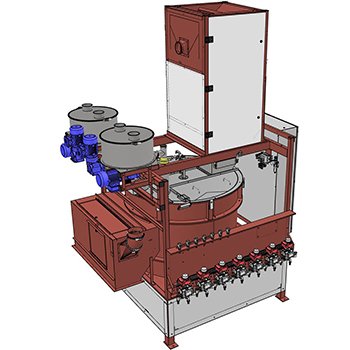

Rotary 25

Rotary coater - (63cm stator drum)

Rotary seed treatment and coating equipment

63cm stator drum (25-inch)

Applications

- Seed treatment

- Film Coating

- Build-up coating

- Pelleting

Target

- Production settings

- Flexible batch sizes for customers with small to medium capacity requirements

Approximate capacity for seed treatment/coating (capacity for selected crops):

- Broad-acre crops = 2 – 25 kg. per batch

- Horticulture crops = 3 – 15kg. per batch

Maximum capacity for filmcoating is about 1500kg. per hr (depending upon seed type and density)

| Features | Benefits |

| Commercial rotary batch technology | Uniform and accurate seed treatment application on every batch |

| Small to medium batches for production settings | Quick and easy scale up |

| Full set of optional automated controls | Greater operator efficiency, consistent product application and higher hourly capacity |

| Standard controls include variable rotor speed, PLC driven control panel, pump & powder feeder (optional) controls and scale system for delivery of seed to run continuous batches | Ease of use, time savings, consistent application and performance every batch |

Product Description

- 63cm drum, rotary seed treatment /coating equipment.

- PLC operated control panel, pump & powder feeder controls (powder feeder is sold optional)

- 2 peristaltic pumps for liquid dose, additional pumps are optional

- Scale system for delivery of seed to run continuous batches

- Side discharge door

- Flexible batch sizes for customers with small to large capacity requirements

- Available 220V 60Hz or three-phase power

| Standard Equipment Rotor / Stator PLC control panel Pump control Automatic loading of seed into treating/ coating chamber Liquid dose system includes two peristaltic pumps | Optional Equipment Powder feeder 1 or 2-inch PLC upgrade, recipe management controls Semi-auto option, scale system not included with Semi-auto option Additional pumps |

Downloads

Related products